PRESS RELEASE Contact: Ron Aarts Phone +1-925-246-5706 Email: ron@innovtec.com RELEASE DATE: FEBRUARY 19, 2013 Innovtec on winning team at [acronym] Magazine Public Sector CAD Awards Innovtec laser scan data accelerated BIM creation and proved project feasibility Walnut Creek, CA, (February 19, 2013) Innovtec announced today that its effort as part of the Lockheed Martin / […]

Orlando International Airport: BP-432 Outbound BHS Upgrades

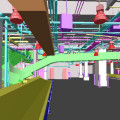

The design/build team in charge of the BP-432 Outbound Baggage Handling Systems Upgrades at Orlando International Airport contracted Innovtec to accurately document the as-built conditions in the 80,000 square-foot bagroom. Vic Thompson, the BHS consultant would used this detailed 3D model to develop a clear right-of-way for the new conveyor. Having an accurate model would streamline the process once final design had begun allowing the manufacturer to install the new conveyor with confidence that each potential obstruction had been accounted for. The contractor Epstein Construction would use the same model to coordinate the installation and relocation of the mechanical, electrical and piping in support of the new system.

Harry Tracy Water Treatment Plant Seismic Retrofit in San Bruno, CA

The Harry Tracy Water Treatment Plant in San Bruno, CA required a major update to make the facility more seismically sound, to improve water treatment capacity and maximize overall reliability. After being awarded the large contract to lead the reconstruction project, Kiewit Infrastructure Group immediately turned to Innovtec knowing the current drawings were outdated and unreliable for the required structural calculations.

LaGuardia Airport Terminal C & D Baggage Handling System (BHS) renovation

Early in 2011, CAGE recruited Innovtec to assist them on the Baggage Handling System (BHS) renovation in Terminals C and D at LaGuardia Airport in NYC. The area undergoing modifications had no reliable as-built drawings on record. CAGE desired a laser scanned, documentation solution with a rapid turnaround so that they could make the BHS updates in a timely, but accurate manner.